CF CD Blade max thickness for each radius. Submarine Design 78 Apron Planning and Design Guidebook Key Points.

Wageningen B Screw Series Propeller Design

Check of risk of cavitation 3.

. In this case the blades tend to stall. Differentiated control of the esc for high motor efficiency and speed performance. BE SURE TO USE A WATT-METER in-line with your power supply TO ENSURE.

This calculator is designed to give any missing value from the 5 variables needed for marine propeller calculations. 30 51 THE SELECTION OF THE MARINE SCREW PROPELLER. 0 prop pitch the distance that a propeller would move forward in one revolution prop slip the efficiency of the prop lower at high speed but perhaps very With the freedom provided by owning a car comes the responsibility of.

Calculation of thrust and torque 2. We Polson Enterprises do not provide assistance in sizing. If we assume that the selected propeller is designed to be most efficient at the designated cruise speed then the required engine power is determined as follows.

13 Required prop pitch for top speed. Select propeller diameter and RPM. Large pitch propellers may have a good efficiency in their design point but may run into trouble when the have to operate at axial velocity.

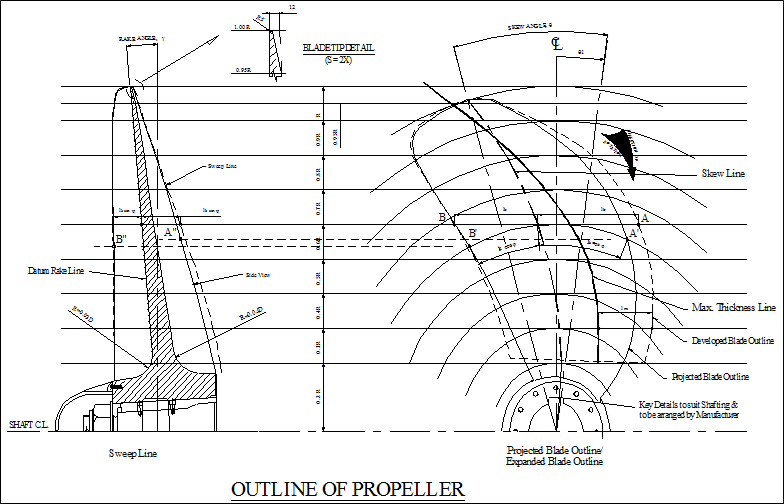

For general propeller design work the ISO specifications usually serve as the criteria for assessment. Propeller Pitch in inches. If you cant fit the indicated diameter due to clearance or have plenty room left the rules.

31 511 Fixed pitch propeller. 34 522 Optimum diameter 36. THE PROPELLER DESIGN PROCESS.

Two inches extra pitch will cut engine rpm by 450. The calculations for each step have been put into the spreadsheet. Propeller Diameter in inches.

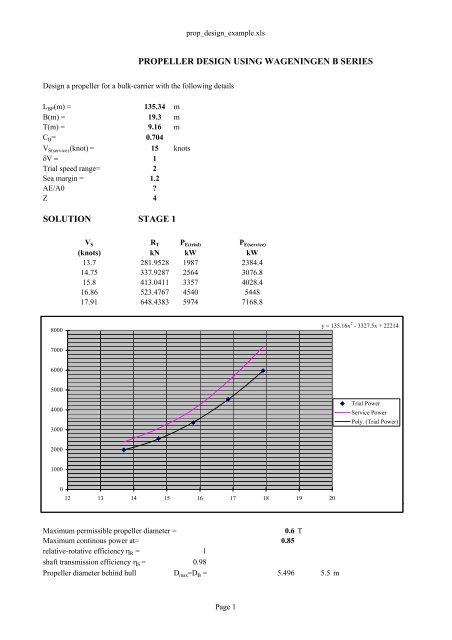

To find a specific citation by accession number. Z 4 SOLUTION STAGE 1 V S R T P E trial P E service knots kN kW kW. â Identify runway and taxiway critical areas that may affect apron.

Take the accession number and add to the end of the link below. 1 Measure static thrust with a variety of propellers. The propeller design calculation consists of three steps.

Aircraft propeller design calculation spreadsheet pdf file download online Nearly all unemployment agencies accept claims online especially in light of the COVID-19 pandemic. Select propeller diameter and RPM. These steps may take place as youre filing your application or they could be the last steps in determining your eligibility.

Take the alphanumeric code at end of the broken hyperlink and add to the end of the link. This is a direct calculation excel sheet to plot expanded profiel shape of propeller blade at particular rR ratio. These tips offer hot key combinations.

33 521 Drawbacks on the definition of the propeller using systematic series. Up to 24 cash back The efficiency of the propeller at the design point required torque at sea level and required rpm at altitude of 18 km were set as responses for each design. Check of risk of cavitation 3.

Aliquot 180 µl of protein stock solution into a microcentrifuge tube and make a series of eight two-fold dilutions into protein dilution buffer by sequentially mixing 90 µl of buffer with 90 µl of the. Some software includes kinematic capabilities that simulate vehicle dynamics using the designed suspension. Calculated by solving second degree eq.

Determination of camber and pitch distribution Calculation of thrust and torque 1. Introduction p 2 2. 1085 Theoretical required prop pitch in inches.

â Design apron and parking areas outside AOA critical areas considering parked positions aircraft maneuvering within the apron and entryexit movements to the airfield. Empirical formula t tc vV 12 vV fc kc ka kt. Determination of camber and pitch distribution Calculation of thrust and torque 1.

5600 Max prop shaft rpm from Torque SHP page 4480 80 of max prop shaft rpm 4052 desired speed expressed as feet per minute. The simplified form is shown to help you put the equation into a calculator or Excel spreadsheet easier. 31 512 Controllable pitch propeller.

Usually the best overall propellers will have a pitch to diameter ratio in the order of 1. How to use my equation to choose a propeller for your design WHEN YOU ARE CAPABLE OF MEASURING STATIC THRUST. A Bp-δ diagram or experience might be used.

Propeller Blade Section Profile using Wageningen B-screw series - Free download as Excel Spreadsheet xls xlsx PDF File pdf Text File txt or read online for free. 090 desired speed divided by max prop shaft rpm to give prop feet per minute. A Bp- diagram or experience might be used.

Sizing Propellers Those wanting to actually size a propeller for a boat determine the best diameter and pitch may find a free downloadable Propeller Calculator program from Castle Marine in the UK. Initial hydrodynamic pitch angle. How to read propeller spec.

This is an automatic calculation from shaft horsepower and rpm at prop on Torque sheet. Induced tangential velocity at blade Induced axial velocity at blade Local axial inflow velocity Kinviscosity Radial lift distribution. The propeller diameter has a big impact on performance.

Average induced axial velocity. The propeller design calculation consists of three steps. P Engine Cruise P Req η P E n g i n e C r u i s e P R e q η If we assume that the efficiency η085 η 085 then we can calculate the engine power required.

One inch diameter 25 inches of pitch. It is intended to be used by turbine design engineers and small manufacturers all over the world who want a low head turbine design suitable for rural electrification. PROPELLER DESIGN USING WAGENINGEN B SERIES Design a propeller for a bulk-carrier with the following details L BP m 13534 m B m 193 m T m 916 m C B 0704 V S service knot 15 knots δV 1 Trial speed range 2 Sea margin 12 AEA0.

THE PRELIMINARY PROPELLER DESIGN. Calculation of thrust and torque 2. 32 52 FIRST STAGE.

ISO 484-1 2015 and ISO 484-2 2015 which now supersede the earlier 1981 standards define the requirements for propellers greater than 25 m and between 080 and 25 m respectively. Surfbaud Freeware Propeller Calculator is an Excel spreadsheet program. 1710 Estimated prop slip at required top speed.

The climb speed with respect to altitude is plotted in Figure 26b based on the filtered data. This is a necessary design element that keeps the drone from rotating uncontrollably. Propeller design calculation spreadsheet Written By ohlmacher Wednesday March 16 2022 Add Comment Edit.

To fix an outdated citation hyperlink.

81249180 Raymer Simplified Aircraft Design Spreadsheet Xls Share Ware Simplified Aircraft Design Spreadsheet For Aircraft Design High School Science Graphing

Propeller Design Calculation Results Download Table

Propeller Blade Thickness Calculation Spreadsheet Www Thenavalarch Com Youtube

0 comments

Post a Comment